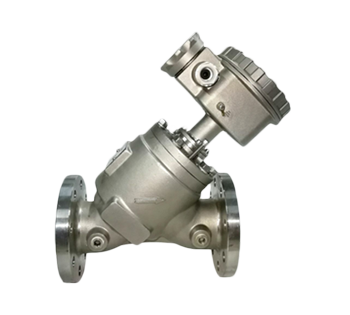

Digital Control Valve

This digital control valve is designed to used for flow control or quantitative loading. It is able to turn on and shut off automatically. It has small resistance to liquid flow, suitable for flow control for all sorts of high viscosity fluids.

• Piston valve switch controlled by stepper motor,

• Long life span of over million times of switching;

• Able to precisely and easily control liquid flow

• Valve working process is free from effect by the viscosity of the liquid.

• Proactive switching, free from effect by the liquid pressure.

Function:

This digital control valve is designed to used for flow control or quantitative loading. It is able to turn on and shut off automatically. It has small resistance to liquid flow, suitable for flow control for all sorts of high viscosity fluids. It has obtained several patents in China.

Application:

It is suitable for used in the situation when liquid flow control/regulation or frequently valve switch is required, or suitable for used in quantitative loading process.

It is suitable for used in the situation when proactive opening of the valve is needed while no any fluid pressure loss is required, and is particularly suitable for situation that valve working rely on its own pressure (gravity) in quantitative loading process.

It is also an ideal upgrade alternation for numeric controlled electro-hydraulic valve, especially suitable for used in the liquid, such as wax, which is easily frozen in the winter.

Applied for liquids of

∗ Chemical Industry: Diesel, gasoline, jet fuel, fuel oil, heavy oil, crude oil, liquefied petroleum gas, chemical raw materials

∗ Chemical lines: Sulfuric acid, hydrochloric acid, alkali, ammonia, etc.

∗ Food Industry: Edible oils, alcohol, beer and various fluids that used in pharmacies and other industries

♦ Piston valve switch controlled by stepper motor,

♦ Long life span of over million times of switching;

♦ It is able to precisely and easily control liquid flow due to the linear regulation of the valve opening;

♦ Valve working process is free from effect by the viscosity of the liquid.

♦ The valve is made of stainless steel, while the sealing ring is made of Teflon engineering plastic. The materials are designed to be able to resistant to acid, alkali, and various chemical solvents;

♦ Proactive switching, free from effect by the liquid pressure, with small fluid resistance.

♦ No noise during the its working and stop working.

♦ Automatically shut down when the power is off.

| Item | Spec |

| Control mode | Switch control; 4~20mA control; RS485 Modbus control; |

| Switching speed | Fully close to fully open: <3.2S Fully open to fully close: <3.2S |

| Working temperature | -40---85℃ |

| Power consumption | Valve acting: <20W Valve remains closed: <2W |

| Power supply | 19 ~ 38V / DC, usually with 24V 220V±20%/AC |

| Electrical interface | 2 X 3/4NPT |

| Valve Casing Material | 304 stainless steel |

| Explosion-proof | CE (ATEX, PED [or SEP] and EMR) ATEX II 2G/D EEx d IIC T6-T4FM/ATEX |

Model Range:

| Model | Nominal diameter | Pressure Level | Dimensions(mm) | Weight(kg) |

| DV80-05D | 50 | PN16/PN25/CLASS 150 | 267*413*190 | 20.8 |

| DV80-08D | 80 | PN16/PN25/CLASS 150 | 310*458*190 | 29.6 |

| DV80-10D | 100 | PN16/PN25/CLASS 150 | 350*494*190 | 52 |

| Your name : | |

| Title : | |

| Contact Number : | |

| E-mail : | |

| Contact Address : | |

| leave Comments : | |