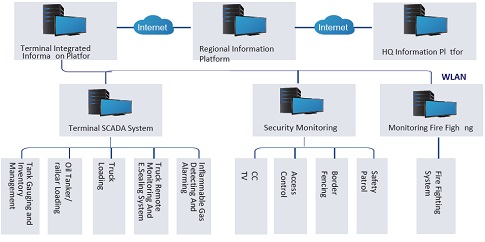

Accuracy, efficiency, security and visualization of the operations are always the key concerns of the terminal owners. Based on 20 years of industrial experiences in TAS related business and close co-operations with prevailing customers in the petrochemical sector, such as Sinopec, CNPC, etc., JOYO M&C has designed and successfully implemented various kind of solutions on terminal automation systems for multiple customers, including those covering the ATG and tank-farm inventory monitoring systems, truck loading/unloading control systems, oil-tanker/rail-car loading/unloading systems, inflammable gas detecting and alarming systems, CCTVs, access control systems, border fencing and alarming systems, remote electronic seal monitoring system, integrated terminal information platforms and integrated security monitoring platforms, etc.

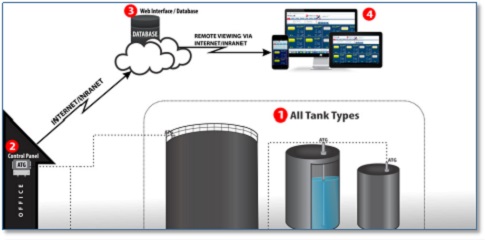

All of the product information and inventory data of the tank are acquired and recorded in the system, which provides a clear view of the tankage data to avoid delivery losses to the customers.

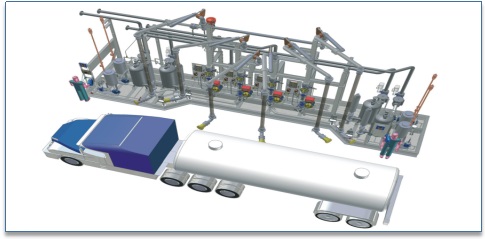

JOYO M&C loading control system is designed to conduct deliveries of oil products in high accuracy, high efficiency and high safety, fully meeting customers’ requirements and expectations in their daily operations. It has been proven a very competitive, cost-effective and reliable solution.

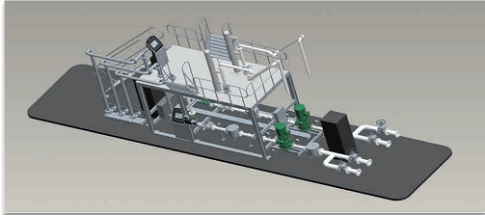

Multiple type of loading skids for trucks or railcars with both standard models and customized models are optional to customers, all being integrated with the batch loading controller, air eliminating strainer, check valve, flow meter, flow valve and the grounding system, etc.

GPS based truck electronic sealing monitoring system is designed to control abnormal/emergency/ insecurity situation or illegal operations on the truck tank which locates in the geographically remote site or in the remote place where the truck beyond the control by HQ.